Focus Four Hazards in Construction: What You Need to Know

Construction sites are dynamic, fast-paced, and full of hazards. Every project brings a set of risks that workers face daily. From heavy machinery to working at heights, the stakes are high. Without proper safety measures, accidents can happen in the blink of an eye.

In this article, we’ll dive into the “Focus Four” hazards in construction—falls, struck-by incidents, electrocutions, and caught-in/between accidents. These four hazards account for the majority of construction-related fatalities, and understanding them is the key to prevention.

What Are the “Focus Four” Hazards?

The “Focus Four” hazards are the leading causes of fatalities in the construction industry. OSHA emphasizes these risks because they are the most common and deadly on job sites. Let’s break down each hazard and explore ways to stay safe.

1. Falls: The Leading Cause of Construction Deaths

Falls are the number one cause of fatalities in construction. Whether it’s from ladders, scaffolding, or roofs, even a short fall can be fatal. Most of these incidents are preventable with the right precautions.

How to prevent falls:

- Always use the proper fall protection equipment, such as harnesses and guardrails.

- Ensure ladders are secure and scaffolding is stable before starting work.

- Train workers on how to recognize and avoid fall hazards.

A clean, organized site also reduces slip and trip risks, keeping workers safer overall.

2. Struck-by Incidents: Watch Out for Moving Objects

Struck-by incidents happen when a worker is hit by a moving object, vehicle, or piece of equipment. These incidents are the second leading cause of construction deaths and can occur in any part of the job site.

Tips to stay safe:

- Wear high-visibility clothing when working around heavy equipment.

- Always wear hard hats to protect against falling objects.

- Never position yourself between moving equipment and a fixed object.

Keeping clear communication with operators and staying aware of your surroundings can help prevent these accidents.

3. Electrocution: The Silent Threat

Electrocutions are another significant risk, often occurring when workers come into contact with power lines or exposed electrical systems. These incidents are particularly dangerous because they can happen suddenly and without warning.

How to reduce the risk:

- Use ground fault circuit interrupters (GFCIs) on all power tools.

- Ensure electrical systems are de-energized before any work begins.

- Maintain a safe distance from overhead power lines.

Regular safety checks and proper insulation of wires can prevent unnecessary exposure to electrical hazards.

4. Caught-in/between Accidents: Avoiding Traps

Caught-in/between accidents happen when workers are caught in or between machinery, materials, or collapsing structures. These accidents can be deadly, especially in confined spaces or trenches.

Safety measures:

- Reinforce trenches and other excavations to prevent collapses.

- Use machinery guards to keep workers safe from moving parts.

- Follow lockout/tagout procedures to ensure equipment is properly de-energized during maintenance.

Quick responses and emergency protocols can save lives when things go wrong.

Why Focus Four Hazards Matter

The Focus Four hazards aren’t just about regulations—they’re about saving lives. These four types of accidents account for over 60% of fatalities in the construction industry. By focusing on proper training, equipment use, and site awareness, companies can make a significant impact on worker safety.

Practical Steps to Improve Safety on Your Site

1. Invest in training: OSHA provides training programs specifically focused on the Focus Four hazards. Regularly educating workers on these risks can reduce accidents.

2. Create a safety-first culture: Reinforce the importance of safety with daily briefings and toolbox talks. Make sure safety is always the top priority.

3. Use technology: Implement safety management software to monitor risks in real-time, log incidents, and ensure OSHA compliance.

4. Maintain equipment: Regular inspections of tools, machinery, and safety equipment can prevent malfunctions that lead to accidents.

5. Encourage open reporting: Create a system where workers feel comfortable reporting unsafe conditions, so hazards are addressed before they lead to injury.

Safetymint for Construction Safety

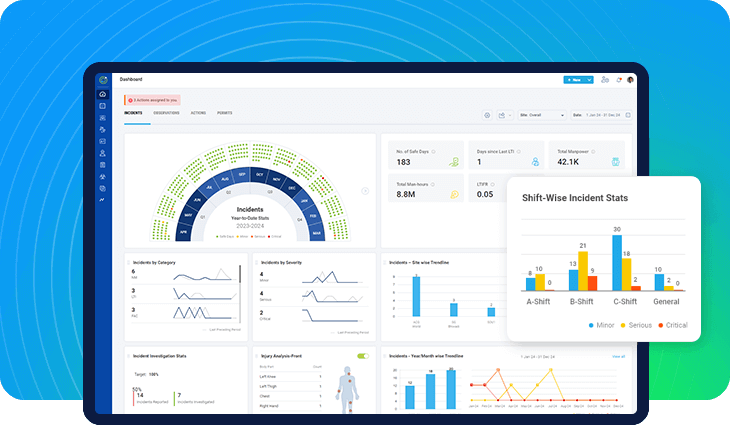

Safetymint offers powerful tools to help manage the risks associated with Focus Four hazards. Our Incident Management module allows quick reporting and tracking of near-misses, accidents, and unsafe conditions—helping you respond before problems escalate.

With the Permit to Work system, ensure that every hazardous task, such as working in confined spaces or electrical maintenance, is managed with the correct permits and approvals. This keeps workers safe and ensures compliance with safety protocols.

The Safety Inspection module helps you conduct thorough site inspections, track hazards, and enforce corrective actions. These tools are essential for reducing risks and maintaining a safe working environment.

Conclusion: Small Steps, Big Impact

By focusing on the “Focus Four” hazards, construction companies can protect workers from the most common and dangerous risks. Simple actions, like better training, clear safety protocols, and the right tools, can create safer job sites for everyone.

Ben Johnson is a dedicated Customer Success Executive at Safetymint. With a strong commitment to excellence, Ben works closely with customers to ensure they fully leverage the capabilities of Safetymint to its fullest potential, aiming to significantly reduce or mitigate safety risks and incidents.