Incident Management Software for Manufacturing: The Key to Smarter, Safer Operations

Every year, manufacturing plants experience thousands of incidents that range from minor accidents to major disasters. These incidents not only put employees’ lives at risk but also cause significant damage to machinery and equipment, resulting in costly downtime and lost productivity. With safety being a top priority for manufacturing plants, it’s crucial to have an effective incident management system in place to prevent, prepare for, and respond to incidents.

But how can you ensure that your manufacturing plant is fully equipped to handle incidents in the most efficient and effective way possible? The answer lies in incident management software.

Incident management software is a comprehensive solution that enables manufacturing plants to streamline their incident management processes, track incidents and observations, and ensure compliance with safety regulations. It can help reduce the number of incidents by identifying potential hazards before they become critical, and it can minimize the impact of incidents when they do occur.

Did you know that in 2020, the private manufacturing industry reported over 373,300 total recordable cases (TRC) of nonfatal injuries and illnesses in the United States alone? This number is a stark reminder of the need for manufacturing plants to prioritize workplace safety and have the right tools in place to mitigate risks.

In this blog post, we’ll explore how incident management software can help manufacturing plants address safety challenges, improve efficiency, and enhance compliance. We’ll also provide tips and best practices for implementing incident management software in your manufacturing plant.

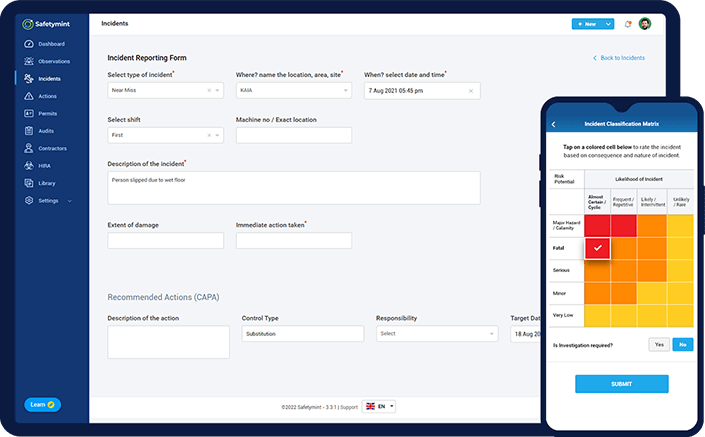

See how Safetymint can help in managing incidents

Challenges in Incident Management for Manufacturing Plants:

Manufacturing plants are prone to various types of incidents, ranging from minor accidents to major disasters that can put workers’ lives at risk and cause significant damage to property and equipment. Here are some of the challenges that manufacturing plants face when it comes to incident management:

Hazardous Materials: Manufacturing plants often work with hazardous materials, such as chemicals and heavy machinery, which can lead to incidents if not handled properly. In fact, the U.S. Chemical Safety Board reports that there are more than 2,000 chemical incidents every year in the United States alone.

Strict Compliance Requirements: Manufacturing plants must adhere to strict safety regulations and compliance requirements set forth by regulatory bodies such as OSHA and EPA. Failure to comply with these regulations can result in hefty fines and reputational damage.

Quick Response Times: In the event of an incident, manufacturing plants must act quickly to contain the situation and minimize the impact on employees and operations. Every second counts, and a delayed response can have severe consequences.

In addition to these challenges, manufacturing plants also face the risk of reputational damage in the event of a major incident. A single incident can have long-lasting effects on a company’s reputation and may result in a loss of business or even closure.

To address these challenges, manufacturing plants need an incident management system that can help them prevent, prepare for, and respond to incidents in the most efficient and effective way possible. Incident management software can provide real-time visibility into incidents, automate incident response procedures, and improve compliance with safety regulations.

According to a recent report by MarketsandMarkets, the incident and emergency management market is expected to grow from USD 121.4 billion in 2022 to USD 163.6 billion by 2027, at a Compound Annual Growth Rate (CAGR) of 6.2% during the forecast period. This growth is attributed to the increasing demand for incident management solutions across various industry verticals, such as manufacturing, construction, oil & gas, mining etc.

Incident Management Software – What it is and how it helps:

Incident management software is a comprehensive solution that helps organizations manage and respond to incidents quickly and efficiently. It is designed to avoid manual incident management processes, provide real-time visibility into incidents, and improve compliance with safety regulations.

At its core, incident management software provides a centralized platform for incident reporting, tracking, and analysis. When an incident occurs, employees can use the software to report the incident, and the system will automatically create an incident record. Incident management software can also notify relevant personnel and departments, assign tasks, and track the progress of incident response efforts.

When selecting an incident management solution for your manufacturing plant, it’s essential to consider the specific features and capabilities that will best meet your needs. Some key features to look for include:

Customizable Incident Forms: Customizable incident forms allow you to capture the specific data points that are most relevant to your organization, making it easier to track and analyze incidents over time.

Real-time Notifications: Real-time notifications ensure that the right people are notified immediately when an incident occurs, enabling a quick and effective response.

Automated Workflows: Automated workflows help streamline incident response efforts by automating tasks and assigning responsibilities to the appropriate personnel.

Analytics and Reporting: Analytics and dashboard reporting capabilities provide insights into incident trends, enabling organizations to identify areas for improvement and implement proactive measures to prevent incidents from occurring in the future.

Benefits of Incident Management Software:

Incident management software can provide several key benefits to manufacturing plants, including:

Improved Safety: Incident management software helps manufacturing plants to identify, manage, and respond to incidents quickly and effectively. By providing real-time incident visibility and automating response procedures, incident management software can help prevent incidents from escalating, reducing the risk of injury to employees and damage to property.

Reduced Downtime: Incidents can cause significant downtime, resulting in lost production time and revenue. Incident management software can help reduce downtime by automating incident response procedures, enabling a quicker response and faster resolution of incidents.

Better Compliance: Compliance with safety regulations and standards is critical for manufacturing plants. Incident management software helps manufacturing plants maintain compliance by automating the tracking and reporting of incidents, ensuring that incidents are appropriately documented and reported to regulatory bodies.

Improved Efficiency: Incident management software streamlines incident response processes, making it easier to identify the root cause of incidents, assign responsibilities, and track the progress of response efforts. This can result in improved efficiency and productivity, as incident response efforts are more streamlined and effective.

Enhanced Risk Management: Incident management software provides manufacturing plants with valuable insights into incident trends, enabling them to identify potential risks and implement proactive measures to prevent incidents from occurring in the future.

Incident Management Best Practices:

Implementing incident management software can be a game-changer for manufacturing plants, but it is important to ensure that the implementation process is done correctly to reap the full benefits. Here are some best practices for successfully implementing incident management software:

Train Employees: It’s crucial to provide comprehensive training to employees on how to use the incident management software effectively. This includes how to report incidents, how to respond to incidents, and how to use the various features of the software.

Establish Procedures: Establishing clear incident management procedures is key to ensuring that the software is used effectively. This includes defining roles and responsibilities, setting escalation paths, and establishing response timeframes.

Regularly Review and Update the System: Incident management software should be reviewed and updated regularly to ensure that it remains effective and relevant. This includes reviewing incident data, identifying areas for improvement, and updating incident management procedures as needed.

Integrate with Other Systems: Incident management software should be integrated with other systems, such as EHS software, to ensure that all incident data is captured and managed in one centralized location.Monitor Performance: It’s essential to monitor the performance of the incident management software regularly. This includes tracking metrics such as leading and lagging indicators, incident resolution time, incident closure rates, and compliance with safety regulations.

Conclusion:

In conclusion, incident management software can be a powerful tool for manufacturing plants to improve safety management, reduce downtime, and ensure compliance with regulations. Manufacturing plants face unique challenges when it comes to incident management, but incident management software can help overcome these challenges.

If you’re considering implementing incident management software in your own manufacturing plant, it’s important to choose a solution like Safetymint that meets your specific needs and requirements. By doing so, you can improve safety, reduce downtime, and ensure compliance with regulations, ultimately leading to a more productive and successful manufacturing plant.

Get started with Safetymint by taking a free trial or requesting an online demo.

Ramesh Nair is the Founder and Principal Partner of Niyati Technologies, the company behind Safetymint.

He’s a dedicated advocate for workplace safety. Ramesh firmly believes that every individual deserves to return home safely after a day’s work. Safetymint, the innovative safety management software, emerged from this conviction. It’s a platform designed to streamline safety management, empower safety professionals, and enhance safety in workplaces.

Through his blog, Ramesh shares insights, best practices, and innovative solutions for workplace safety. Visit his social media profiles to follow him for regular updates.