10 Critical Safety Incidents You Can’t Afford to Ignore

Safety at the workplace is non-negotiable.

Every day, countless safety incidents occur that can disrupt operations and harm employees. Ignoring these incidents isn’t an option. Whether you’re in construction, manufacturing, or any other industry, knowing the common safety hazards is crucial.

In this post, we’ll explore ten critical safety incidents that demand your immediate attention. From slips and falls to chemical exposures, each incident poses unique risks. We’ll also share tips on how to safeguard against these dangers.

Ready to learn more? Let’s get started!

1. Slips, Trips, and Falls

Slips, trips, and falls are the most common workplace accidents. They account for over a third of all major workplace injuries. Ensuring walkways are clear and spills are promptly cleaned can significantly reduce these incidents. Use anti-slip mats in wet areas and provide proper lighting to avoid accidents. According to the National Safety Council, these incidents result in 27% of all nonfatal workplace injuries.

2. Machinery Accidents

Working with machinery poses significant risks. Improper handling or malfunctioning equipment can lead to severe injuries. Regular maintenance and proper training are essential to prevent these accidents. Ensure all machines have appropriate guards and emergency stop buttons. The Occupational Safety and Health Administration (OSHA) reports that machinery-related injuries are a leading cause of workplace fatalities .

3. Electrical Hazards

Electricity is a silent hazard in many workplaces. Faulty wiring, exposed wires, and improper use of electrical equipment can lead to shocks, burns, or even fatalities. Regular inspections and adherence to electrical safety standards are crucial. The Electrical Safety Foundation International (ESFI) states that electrical incidents cause about 4,000 injuries annually.

4. Falls from Heights

Falls from heights are prevalent in construction and industrial settings. These incidents often result in serious injuries or fatalities. Providing proper fall protection equipment and training can prevent such accidents. OSHA mandates specific safety measures for working at heights, including guardrails and harness systems.

5. Chemical Exposures

Exposure to hazardous chemicals can cause immediate injuries or long-term health issues. Proper storage, labeling, and use of PPE are vital. Employees should be trained on handling chemicals safely. According to the Bureau of Labor Statistics, chemical exposures cause thousands of workplace injuries each year.

6. Fires and Explosions

Workplace fires and explosions can result from flammable materials, faulty electrical equipment, or improper storage of chemicals. Implementing strict fire safety protocols and regular drills can save lives. The National Fire Protection Association (NFPA) provides guidelines for fire safety in workplaces.

7. Overexertion and Repetitive Strain Injuries

Overexertion injuries, including strains and sprains, are common in physically demanding jobs. Repetitive tasks can also lead to chronic issues like carpal tunnel syndrome. Encourage regular breaks and ergonomic practices to minimize these risks. The National Institute for Occupational Safety and Health (NIOSH) offers resources on preventing these injuries.

8. Vehicle-Related Accidents

Workplace vehicle accidents involve forklifts, trucks, and other machinery. Proper training and regular vehicle maintenance are crucial. Designated pathways and clear signage can prevent collisions. The National Safety Council highlights that vehicle-related incidents are a significant cause of workplace injuries.

9. Workplace Violence

Unfortunately, workplace violence is a reality in many industries. It includes physical assaults, threats, or verbal abuse. Implementing a zero-tolerance policy and providing conflict resolution training can help. According to OSHA, nearly 2 million American workers report being victims of workplace violence annually.

10. Confined Space Incidents

Working in confined spaces poses unique risks such as asphyxiation, entrapment, or exposure to hazardous substances. Proper training, monitoring, and the use of PPE are essential for safety. OSHA provides comprehensive guidelines on confined space safety to prevent these incidents.

By recognizing and addressing these common safety incidents, you can create a safer, more productive workplace.

Safetymint for Effective Incident Management

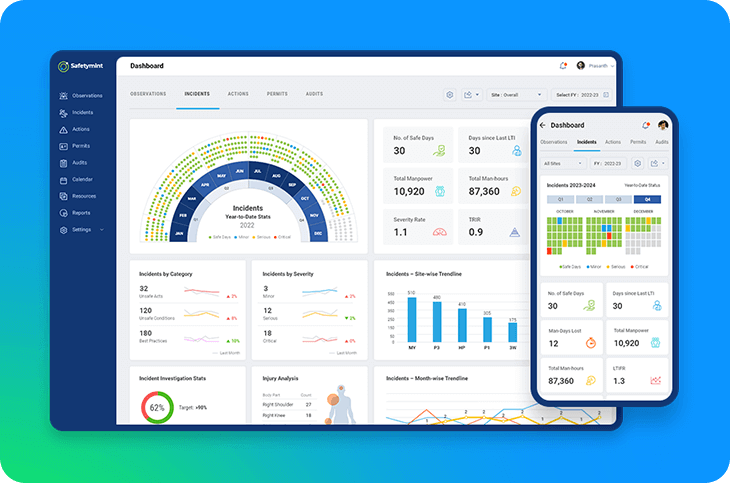

Managing safety incidents efficiently is crucial for maintaining a safe workplace. Safetymint offers a comprehensive solution to help organizations handle incidents effectively. With our cloud-based safety management software, you can streamline the entire incident management process from reporting to resolution.

Here’s how Safetymint can enhance your incident management efforts:

Easy Reporting: Report incidents, observations, and near-misses quickly using our user-friendly web and mobile applications.

Real-Time Notifications: Receive instant alerts and notifications when an incident is reported, an action is assigned, or an action is due.

Custom Workflows: Create and customize workflows to match your organization’s specific incident management processes.

Root Cause Analysis: Conduct thorough investigations using our 5-step process, including root cause analysis and corrective and preventive actions (CAPA).

Action Tracking: Keep track of all assigned actions and ensure timely resolution with our action tracking features.

Digital Signatures: Approve investigations with secure digital signatures.

Lessons Learned: Create a knowledge repository of lessons learned from past incidents to educate and prevent future occurrences.

Detailed Dashboards: Monitor incident trends and performance metrics with our intuitive dashboards and data analytics tools.

Comprehensive Reports: Generate detailed reports after each investigation, providing insights and documentation for future reference.

Customizable and Scalable: Tailor the software to meet your organization’s unique requirements and scale as your needs grow. Deploy it on the cloud or on-premise based on your preference.

By integrating Safetymint into your safety management strategy, you can ensure that every incident is handled efficiently and effectively, fostering a safer work environment for everyone. Stay proactive and protect your workforce with Safetymint.

Ben Johnson is a dedicated Customer Success Executive at Safetymint. With a strong commitment to excellence, Ben works closely with customers to ensure they fully leverage the capabilities of Safetymint to its fullest potential, aiming to significantly reduce or mitigate safety risks and incidents.