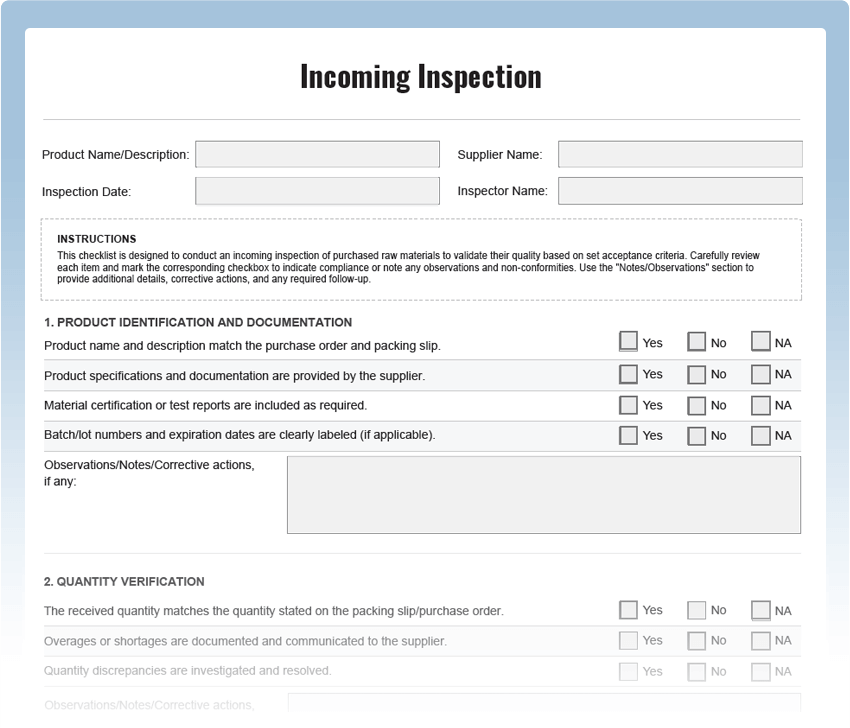

Incoming Inspection Checklist

Ensure the quality and compliance of incoming materials and products with our comprehensive Incoming Inspection Checklist. This free PDF template covers all essential aspects of inspecting and verifying incoming items, empowering you to maintain high standards and deliver reliable products to your customers.

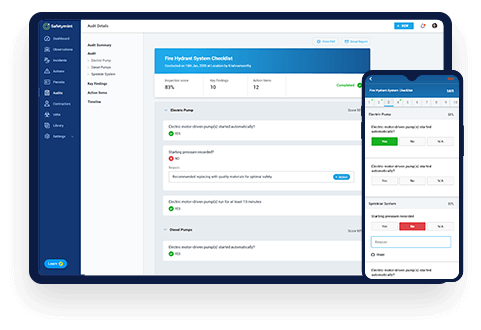

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is an Incoming Inspection Checklist?

An Incoming Inspection Checklist is a systematic tool used to inspect and assess incoming materials, components, or products for quality, compliance, and conformance to specifications. It includes a series of checkpoints designed to ensure that incoming items meet the required standards before being used in production or delivered to customers. Regular incoming inspections are crucial for maintaining product quality and meeting customer expectations.

Key Areas to Inspect in Incoming Items:

- Physical Inspection: Check for any visible damage, defects, or discrepancies in the appearance of the incoming items.

- Dimensions and Measurements: Verify that the dimensions and measurements of the items align with the required specifications.

- Material Quality: Assess the material’s quality and composition to ensure it meets the required standards.

- Functionality and Performance: Test the functionality and performance of the items to ensure they meet the intended purpose.

- Documentation and Certifications: Review accompanying documentation and certifications for accuracy and completeness.

- Packaging and Labeling: Ensure that the packaging and labeling of the items are correct and intact.

Common Issues Identified in Incoming Inspection:

Frequent issues found during incoming inspections include:

- Non-Conforming Items: Incoming items that do not meet the specified quality standards.

- Damaged Shipments: Items arriving with visible damage due to transportation or handling.

- Incorrect Specifications: Items that do not match the required dimensions or material specifications.

- Missing Documentation: Incomplete or inaccurate documentation accompanying the incoming items.

Incoming Inspection Best Practices:

- Standard Operating Procedures: Develop clear and comprehensive standard operating procedures (SOPs) for incoming inspections.

- Well-Trained Inspectors: Ensure that inspectors are well-trained in inspection techniques and quality standards.

- Sampling Plans: Implement appropriate sampling plans to ensure a representative inspection process.

- Timely Inspections: Conduct incoming inspections promptly upon receipt of materials or products.

- Communication with Suppliers: Provide feedback to suppliers regarding non-conforming items and quality issues.