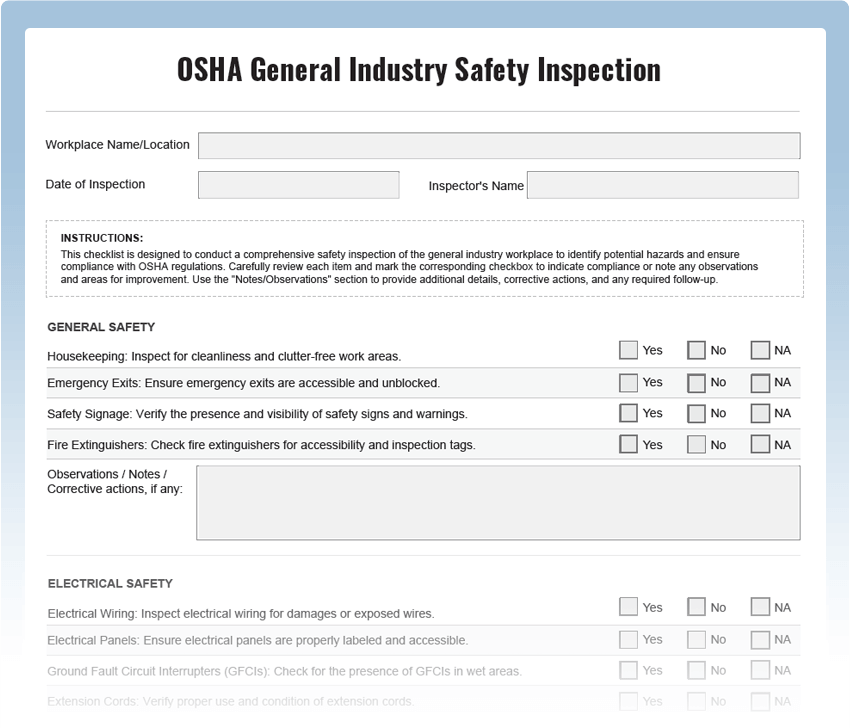

OSHA General Industry Safety Inspection Checklist

Ensure the safety and well-being of your employees in the general industry with our comprehensive OSHA General Industry Safety Inspection Checklist. This free PDF template covers all critical aspects of workplace safety, empowering you to identify potential hazards, perform regular inspections, and maintain compliance with OSHA regulations.

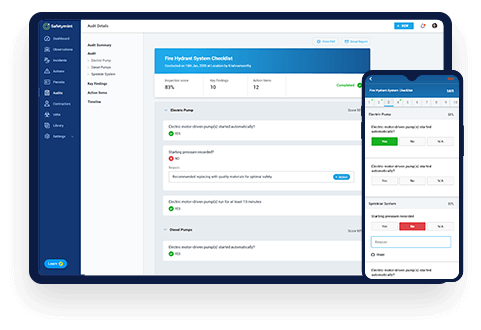

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is an OSHA General Industry Safety Inspection Checklist?

An OSHA General Industry Safety Inspection Checklist is a systematic tool used to evaluate the safety conditions of workplaces in general industry settings. It includes a series of checkpoints designed to inspect various areas and processes to ensure compliance with OSHA regulations and industry best practices. Regular safety inspections are essential for preventing accidents, promoting a safety culture, and providing a secure work environment for employees.

Key Areas to Inspect in General Industry:

- Housekeeping: Assess the overall cleanliness and organization to prevent slips, trips, and falls.

- Machine Guarding: Check for proper machine guarding to protect employees from moving parts.

- Hazard Communication: Review chemical labels, safety data sheets, and employee training.

- Electrical Safety: Verify that electrical systems and equipment are in safe working condition.

- Personal Protective Equipment (PPE): Ensure that employees have access to and use appropriate PPE.

- Fire Protection: Check for the presence and functionality of fire extinguishers and exit routes.

- Emergency Preparedness: Evaluate emergency response plans and the accessibility of emergency equipment.

Common General Industry Inspection Findings:

Frequent issues found during general industry inspections include:

- Slippery Surfaces: Floors or work areas with spills or debris causing slip hazards.

- Unsafe Machinery: Lack of machine guarding or improper use of equipment.

- Hazardous Material Handling: Improper storage or handling of chemicals and substances.

- Electrical Hazards: Unsafe wiring or inadequate electrical system maintenance.

General Industry Safety Inspection Best Practices:

- Regular Inspections: Conduct routine safety inspections to identify potential hazards and risks.

- Corrective Actions: Address any identified safety deficiencies promptly and follow up on corrective measures.

- Employee Training: Provide comprehensive safety training to all employees, tailored to their specific tasks.

- Safety Committees: Establish safety committees to involve employees in safety improvement initiatives.

- Safety Reporting: Encourage employees to report safety concerns and near-miss incidents.

Also read: Top 10 OSHA inspection checklists