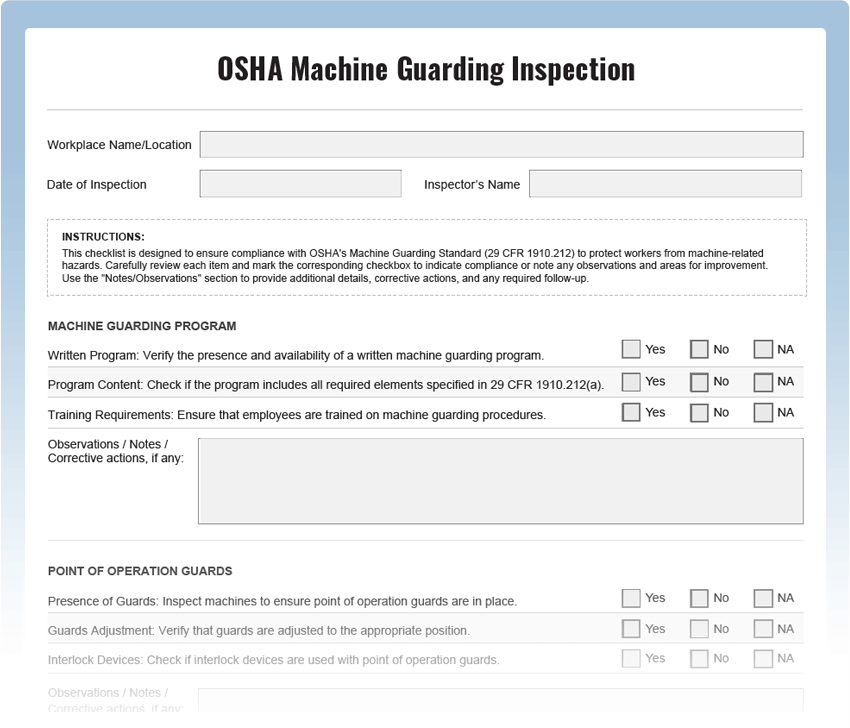

OSHA Machine Guarding Inspection Checklist

Ensure the safety of your workers around machinery with our comprehensive OSHA Machine Guarding Inspection Checklist. This free PDF template covers all critical aspects of machine guarding, empowering you to identify potential hazards, perform regular inspections, and maintain a secure work environment.

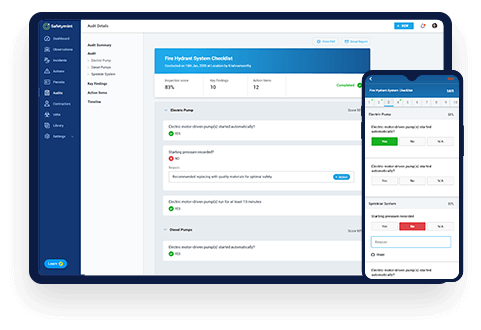

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is an OSHA Machine Guarding Inspection Checklist?

An OSHA Machine Guarding Inspection Checklist is a systematic tool used to assess the safety conditions of machinery in the workplace. It includes a series of checkpoints designed to inspect machine guards, barriers, and safety devices that protect employees from hazardous machine parts. Regular machine guarding inspections are vital for preventing accidents, reducing the risk of injuries, and complying with OSHA regulations.

Key Areas to Inspect for Machine Guarding:

- Machine Guards: Check the presence and adequacy of machine guards on all hazardous areas.

- Barrier Systems: Assess the effectiveness of barrier systems, such as fencing or enclosures.

- Emergency Stop Devices: Verify the accessibility and functionality of emergency stop buttons.

- Interlock Systems: Check interlock systems that prevent machine operation when guards are open.

- Safety Signs and Labels: Ensure that appropriate warning signs and labels are in place.

- Safety Devices: Inspect safety devices like light curtains or pressure mats for proper functioning.

Common Machine Guarding Inspection Findings:

Frequent issues found during machine guarding inspections include:

- Missing or Inadequate Guards: Unprotected moving parts, posing a risk of entanglement or contact.

- Damaged Guards: Guards with cracks, dents, or other damage that compromise their effectiveness.

- Bypassed Safety Devices: Safety devices overridden or bypassed, increasing the risk of accidents.

- Inadequate Warning Signs: Absence of clear warning signs, increasing the potential for injuries.

Machine Guarding Inspection Best Practices:

- Regular Inspections: Conduct routine machine guarding inspections and address any issues promptly.

- Training and Awareness: Provide comprehensive training to employees on machine safety and guarding.

- Maintenance: Regularly maintain and repair machine guards and safety devices.

- Lockout/Tagout Procedures: Implement proper lockout/tagout procedures during maintenance.

- Employee Involvement: Involve employees in identifying machine guarding concerns.

Also read: Top 10 OSHA inspection checklists