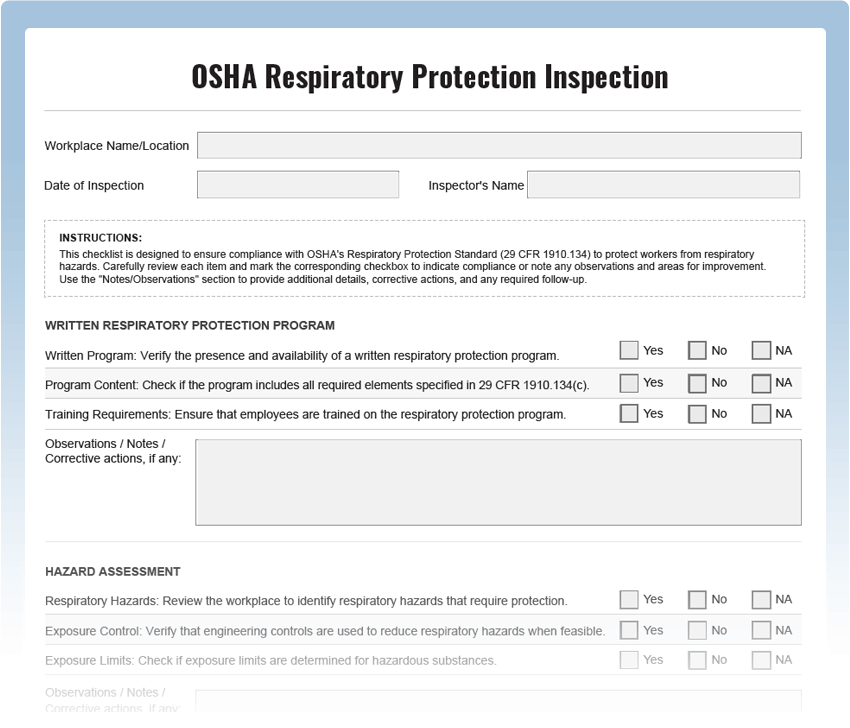

OSHA Respiratory Protection Inspection Checklist

Protect your workforce from respiratory hazards with our comprehensive OSHA Respiratory Protection Inspection Checklist. This free PDF template covers all critical aspects of respiratory protection equipment and practices, empowering you to identify potential hazards, perform regular inspections, and maintain a safe work environment.

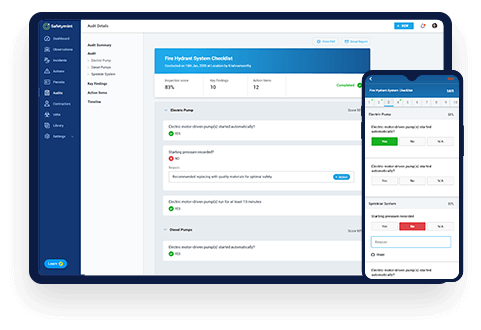

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is an OSHA Respiratory Protection Inspection Checklist?

An OSHA Respiratory Protection Inspection Checklist is a systematic tool used to assess the safety conditions of respiratory protection equipment and practices in the workplace. It includes a series of checkpoints designed to inspect respirators, filters, cartridges, and related safety measures. Regular respiratory protection inspections are crucial for preventing respiratory illnesses, protecting workers from harmful substances, and complying with OSHA regulations.

Key Areas to Inspect for Respiratory Protection:

- Respirator Condition: Check the overall condition of respirators for signs of wear, damage, or deterioration.

- Proper Fit: Ensure that each employee’s respirator fits properly and comfortably.

- Filter/Cartridge Integrity: Inspect filters and cartridges for effectiveness and proper attachment.

- Valves and Exhalation Devices: Verify that valves and exhalation devices function correctly.

- Airflow and Breathing Resistance: Test the airflow and breathing resistance of powered and supplied-air respirators.

- Training and User Compliance: Assess employee training on proper respirator use and compliance.

Common Respiratory Protection Inspection Findings:

Frequent issues found during respiratory protection inspections include:

- Damaged Respirators: Respirators with tears, cracks, or other damage that may compromise their effectiveness.

- Improper Fit: Ill-fitting respirators that may allow contaminants to enter.

- Expired Filters/Cartridges: Filters or cartridges beyond their recommended service life.

Respiratory Protection Inspection Best Practices:

- Scheduled Inspections: Conduct routine respiratory protection inspections at scheduled intervals.

- User Seal Checks: Encourage employees to perform user seal checks before each use.

- Proper Storage: Store respirators in a clean, dry, and designated area.

- Training and Fit Testing: Provide comprehensive training and fit testing for all employees using respirators.

- Equipment Maintenance: Regularly clean and maintain respirators and replace filters/cartridges as needed.

Also read: Top 10 OSHA inspection checklists