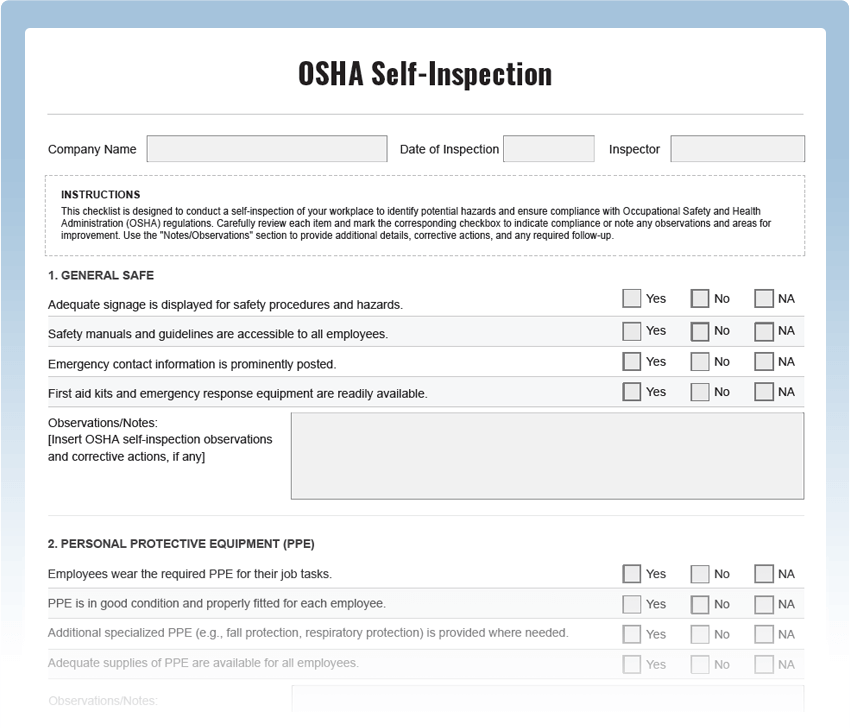

OSHA Self Inspection Checklist

Empower your organization to maintain compliance with Occupational Safety and Health Administration (OSHA) regulations using our comprehensive OSHA Self Inspection Checklist. This free PDF template provides a structured framework to conduct internal safety inspections, ensuring that your workplace meets OSHA standards and promotes the well-being of your employees.

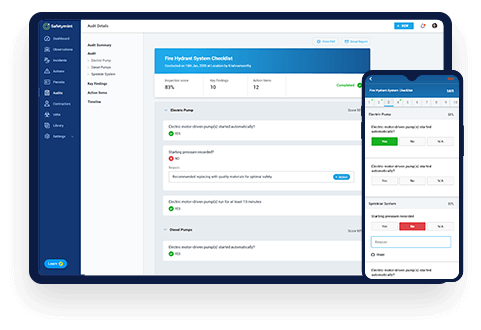

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is an OSHA Self Inspection Checklist?

An OSHA Self Inspection Checklist is a systematic tool used to evaluate workplace safety and identify potential OSHA compliance issues. It comprises a series of checkpoints aligned with OSHA regulations and best practices. Regular self-inspections are critical for maintaining a safe work environment, reducing accidents, and avoiding potential fines or penalties.

Key Areas to Inspect in an OSHA Self Inspection:

- Hazard Communication: Assess the availability and accessibility of Safety Data Sheets (SDS) for hazardous chemicals, and ensure proper labeling.

- Fire Safety: Verify the presence and condition of fire extinguishers, emergency exits, and evacuation routes.

- Electrical Safety: Inspect electrical panels, wiring, and outlets for potential hazards and compliance with electrical standards.

- Machine Guarding: Check that all machines are adequately guarded to prevent employee contact with moving parts.

- Personal Protective Equipment (PPE): Ensure that appropriate PPE is provided, used, and maintained for employees’ safety.

- Ladder and Scaffold Safety: Assess the condition and proper use of ladders and scaffolds to prevent falls.

- Confined Spaces: Identify confined spaces and assess compliance with safety measures for entry and rescue procedures.

- Recordkeeping and Reporting: Review OSHA recordkeeping requirements and ensure accurate reporting of incidents.

Common OSHA Compliance Issues:

Failure to comply with OSHA regulations can result in various issues, such as:

- Exposure to Hazardous Materials: Inadequate hazard communication and handling of hazardous substances.

- Slips, Trips, and Falls: Poor housekeeping and lack of proper walking surfaces and fall protection.

- Electrical Hazards: Improperly maintained electrical systems and equipment.

- Machine Hazards: Lack of machine guarding and employee training on machine operation.

- Confined Space Risks: Inadequate training and lack of safety protocols for confined space entry.

OSHA Self Inspection Best Practices:

- Scheduled Inspections: Establish a routine self-inspection schedule to regularly assess workplace safety.

- Involvement of Employees: Involve employees in the inspection process to gain valuable insights and increase safety ownership.

- Corrective Actions: Promptly address any identified hazards and implement corrective actions.

- OSHA Training: Provide OSHA compliance training to employees and management.

- OSHA Standards Updates: Stay informed about changes to OSHA regulations and adjust inspection practices accordingly.

Also read: Top 10 OSHA inspection checklists