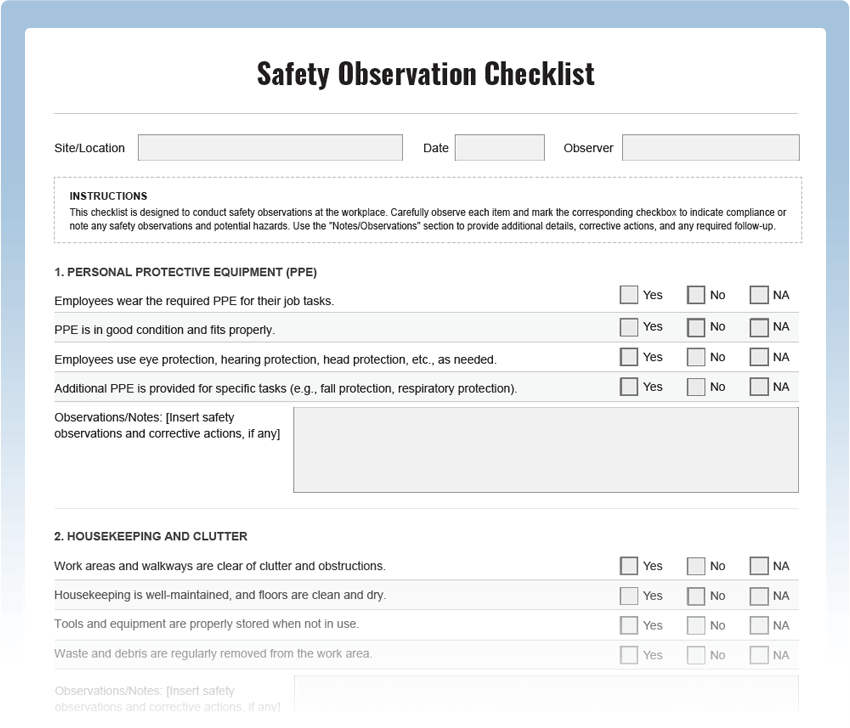

Observation Inspection Checklist

Enhance safety and identify potential risks in your workplace with our comprehensive Observation Inspection Checklist. This free PDF template is designed to help you systematically observe and record safety-related behaviors, conditions, and practices, enabling you to proactively address hazards and promote a culture of safety.

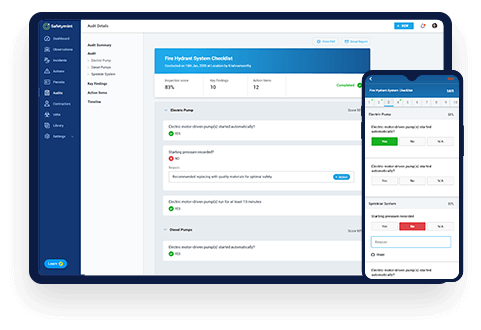

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is an Observation Inspection Checklist?

An Observation Inspection Checklist is a systematic tool used to conduct safety observations in the workplace. It includes a series of checkpoints designed to observe and assess various safety-related aspects, such as employee behaviors, equipment conditions, and adherence to safety protocols. Regular safety observations are crucial to prevent accidents, improve safety practices, and create a safe working environment.

Key Areas to Observe in an Observation Inspection:

- Employee Behaviors: Observe if employees are following safety procedures, wearing PPE, and using equipment correctly.

- Housekeeping Standards: Assess the general cleanliness and organization of work areas to prevent slip and trip hazards.

- Equipment Condition: Observe the condition of machinery and tools to ensure proper functioning and identify maintenance needs.

- Proper Lifting Techniques: Assess if employees are using proper lifting techniques to avoid musculoskeletal injuries.

- Safety Signage: Verify the presence and visibility of safety signs and warning labels throughout the workplace.

- Emergency Preparedness: Observe if employees are aware of emergency procedures and know the location of emergency exits and equipment.

- Chemical Safety: Ensure that employees are following proper procedures for handling and storing hazardous substances.

Common Observations for Improvement:

Safety observations may uncover areas that need improvement, including:

- Unsafe Practices: Identifying employees not using PPE or not following safety guidelines.

- Lack of Training: Noticing workers who lack proper training for their assigned tasks.

- Maintenance Issues: Noting equipment in need of repair or maintenance.

- Housekeeping Lapses: Observing cluttered or untidy work areas.

- Non-Compliance: Identifying instances where safety regulations are not being followed.

Observation Inspection Best Practices:

- Unannounced Observations: Conduct observations at various times to get a comprehensive view of daily operations.

- Positive Reinforcement: Recognize and reward safe behaviors to encourage a culture of safety.

- Constructive Feedback: Provide constructive feedback to employees, highlighting areas for improvement.

- Manager Involvement: Encourage managers and supervisors to participate in safety observations.

- Continuous Improvement: Use observation data to identify trends and implement proactive safety measures.