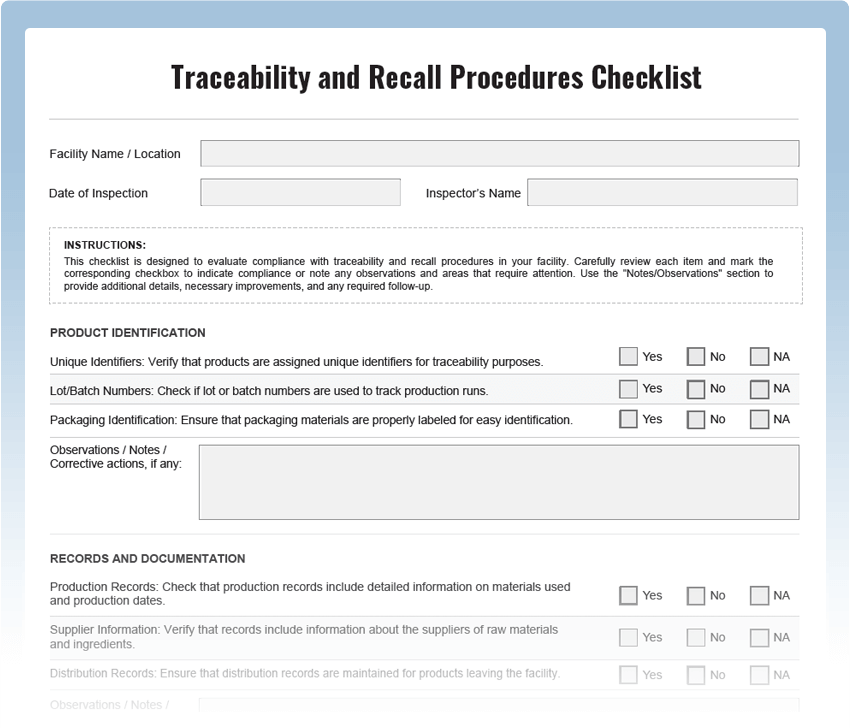

Traceability and Recall Procedure Checklist

Ensure effective traceability and recall procedures with our comprehensive Traceability and Recall Procedure Checklist. This free PDF template is designed to evaluate compliance with traceability and recall processes in your facility. It covers all critical aspects of product traceability, batch identification, record-keeping, and recall readiness, empowering your business to respond swiftly and efficiently in the event of a product recall.

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is a Traceability and Recall Procedure Checklist?

A Traceability and Recall Procedure Checklist is a systematic tool used to assess the implementation of traceability and recall processes in a facility. It includes a series of checkpoints designed to inspect various aspects of traceability, such as product identification, labeling, coding, and record-keeping. The checklist also evaluates the readiness of recall procedures, ensuring that businesses can efficiently trace and retrieve products from the market in case of safety concerns or non-compliance.

Key Areas to Inspect in a Traceability and Recall Procedure Checklist:

- Product Identification: Verify that products are properly labeled with batch codes and traceability information.

- Record-Keeping: Assess the accuracy and completeness of records related to raw materials, production, and distribution.

- Supplier Traceability: Review traceability practices for raw materials and ingredients from suppliers.

- Product Coding and Expiry: Check the proper coding of products and adherence to expiry date guidelines.

- Recall Plan: Evaluate the existence and effectiveness of a recall plan and team.

- Mock Recall Exercises: Verify that mock recall exercises are regularly conducted and documented.

Common Traceability and Recall Checklist Findings:

- Frequent issues found during traceability and recall inspections include:

- Incomplete Record-Keeping: Missing or inaccurate records hampering traceability efforts.

- Lack of Supplier Traceability: Inability to trace raw materials to their respective suppliers.

- Non-Existent Recall Plan: Absence of a clear and tested procedure for product recalls.

Traceability and Recall Checklist Best Practices:

- Regular Audits: Conduct routine traceability and recall audits to ensure ongoing compliance.

- Supplier Collaboration: Work closely with suppliers to improve traceability across the supply chain.

- Swift Communication: Establish clear communication channels for prompt recall notifications.

- Continuous Improvement: Use audit findings to enhance traceability and recall processes.