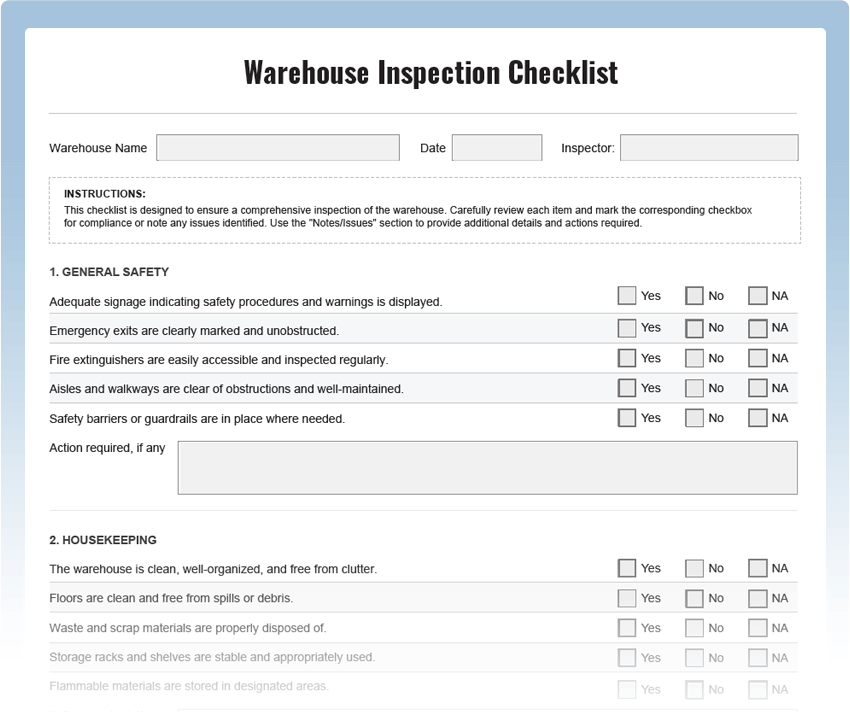

Warehouse Inspection Checklist

Ensure the safety and efficiency of your warehouse operations with our comprehensive Warehouse Inspection Checklist. This free PDF template covers all essential aspects of a thorough warehouse inspection, empowering you to identify potential hazards and maintain a secure work environment.

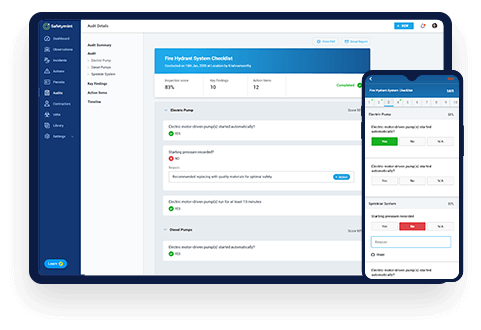

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is a Warehouse Inspection Checklist?

A Warehouse Inspection Checklist is a systematic tool used to assess the condition and safety of a warehouse. It encompasses a series of checkpoints designed to evaluate equipment, storage areas, and safety protocols. Conducting regular warehouse inspections is crucial to prevent accidents, optimize workflows, and comply with safety regulations.

Key Things to Inspect in a Warehouse:

- Storage Racking: Check for any signs of damage, instability, or overloading in the storage racks to prevent collapses and falling items.

- Fire Safety Measures: Inspect fire extinguishers, sprinkler systems, and emergency exits to ensure they are fully functional and accessible.

- Housekeeping Standards: Assess general cleanliness, clutter, and debris, as proper housekeeping minimizes tripping hazards and facilitates smooth operations.

- Material Handling Equipment: Examine forklifts, pallet jacks, and conveyor belts for maintenance issues and confirm that operators are trained and following safety protocols.

- Electrical Systems: Inspect wiring, lighting, and electrical outlets to eliminate potential fire hazards and electrical accidents.

- Safety Signage: Ensure clear and visible signage for hazards, emergency routes, and safety procedures.

- Personal Protective Equipment (PPE): Check that appropriate PPE is available and being used by warehouse staff.

Common Warehouse Hazards:

Warehouses can pose various risks to workers and the facility itself. Some common hazards include:

- Slips, Trips, and Falls: Wet floors, cluttered aisles, and uneven surfaces can lead to slips, trips, and falls.

- Forklift Accidents: Improper operation of forklifts can result in collisions, tip-overs, and injuries.

- Fires: Electrical faults, flammable materials, and inadequate fire safety measures can lead to devastating fires.

- Inadequate Ventilation: Poor air circulation may lead to respiratory issues and reduce air quality.

- Material Handling Risks: Incorrect manual handling of heavy items can cause musculoskeletal injuries.

Warehouse Inspection Best Practices:

- Regular Inspections: Conduct scheduled inspections to identify and address potential issues proactively.

- Engage Employees: Involve warehouse staff in the inspection process to gather valuable insights and increase safety awareness.

- Document Findings: Maintain detailed records of inspections and actions taken to track improvements and compliance.

- Address Hazards Promptly: Prioritize the immediate correction of identified hazards to prevent accidents.

- Training and Education: Provide ongoing training to employees on safety protocols, equipment operation, and emergency procedures.

- Stay Updated: Keep abreast of changing safety regulations and industry best practices.