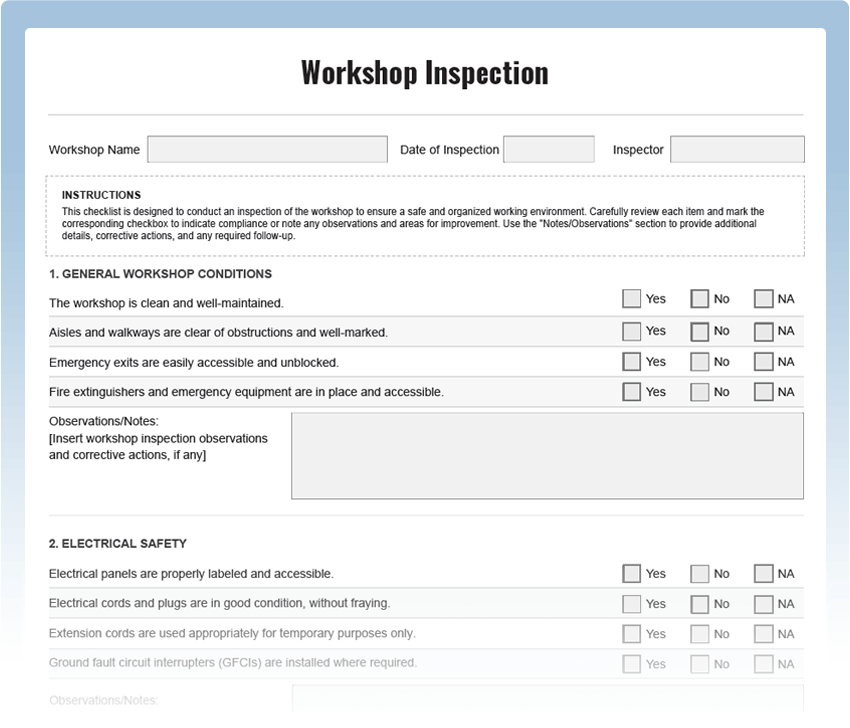

Workshop Inspection Checklist

Maintain a safe and productive workshop environment with our comprehensive Workshop Inspection Checklist. This free PDF template covers all essential aspects of workshop safety, equipment maintenance, and housekeeping, enabling you to identify potential hazards, address issues promptly, and ensure the well-being of your workers.

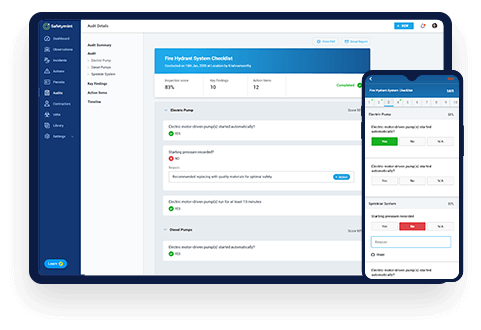

Digitize this Checklist on Safetymint

- Create unlimited, customized checklists

- Add Actions, with automated reminders

- Works seamlessly with or without internet

- Access via web browsers, mobile or tablets

What is a Workshop Inspection Checklist?

A Workshop Inspection Checklist is a systematic tool used to assess workshop safety, compliance with safety regulations, and equipment condition. It includes a series of checkpoints designed to ensure that the workshop is a safe and efficient space for employees to carry out their tasks. Regular workshop inspections are crucial to prevent accidents, maintain equipment functionality, and promote a culture of safety.

Key Areas to Inspect in Workshop Safety:

- Workshop Layout: Assess the arrangement of equipment and workstations to ensure smooth workflow and prevent obstructions.

- Safety Signage: Verify the presence and visibility of safety signs, warning labels, and emergency exit signs.

- Electrical Safety: Check electrical wiring, outlets, and equipment for potential hazards and compliance with safety standards.

- Machine Safety Guards: Ensure that all machines have proper safety guards and that employees use them correctly.

- Personal Protective Equipment (PPE): Check that employees have access to and use appropriate PPE, such as safety glasses, gloves, and ear protection.

- Material Storage: Assess the organization and storage of materials to prevent tripping hazards and ensure easy access.

- Fire Safety Equipment: Verify the presence and condition of fire extinguishers and fire suppression systems.

- Housekeeping: Assess overall cleanliness and organization to prevent slips, trips, and falls.

Common Workshop Safety Hazards:

Failure to address workshop safety hazards can lead to:

- Accidents and Injuries: Inadequate safety measures can result in workplace accidents and injuries.

- Equipment Malfunctions: Poor maintenance can lead to machine breakdowns and operational disruptions.

- Electrical Incidents: Faulty electrical systems can cause electrocutions and fires.

- Tripping Hazards: Cluttered or disorganized work areas can lead to slips, trips, and falls.

- Noise and Hearing Damage: Prolonged exposure to loud noise without proper hearing protection can cause hearing damage.

Workshop Inspection Best Practices:

- Regular Inspections: Conduct frequent workshop inspections to identify and address potential risks promptly.

- Training and Education: Provide comprehensive safety training to all workshop personnel.

- Corrective Actions: Take immediate corrective actions to address any deficiencies found during inspections.

- Preventive Maintenance: Implement a preventive maintenance program for workshop equipment.

- Safety Meetings: Hold regular safety meetings to discuss safety concerns and best practices.